Recycling

Why recycling matters

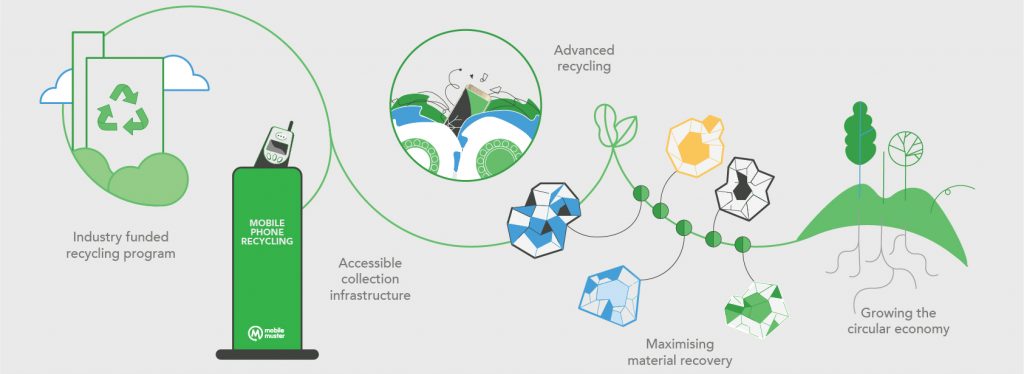

Through recycling MobileMuster transforms the components from mobile phone waste into valuable materials for reuse. It means that fewer raw materials need to be extracted and processed to make new products. By recycling your mobile phone today you will be helping reduce the impact on the environment of tomorrow.

Follow the journey of what happens when you drop off your mobile phone for recycling at a MobileMuster collection point. You will see how the phones are dismantled and discover the materials that can be recovered. We will show you how recycling efforts — big and small have a lasting, positive impact on our environment.

Learn more

What happens when you recycle?

The recycling journey

Carbon neutral

When you recycle with MobileMuster it is 100% carbon neutral.

MobileMuster is committed to reducing our carbon emissions and where necessary offsetting all the emissions associated with the product stewardship program. It means that all our operations have net zero carbon impact. MobileMuster is the first product stewardship program in Australia to achieve certification under Climate Active.

MobileMuster has purchased carbon offsets to take responsibility for the unavoidable emissions we produce. We offset our impact through South Pole, supporting a solar power project in Taiwan, and a conservation project in Mount Sandy, South Australia to protect native biodiversity.

Our process

Through our recycling process over 89% of the materials in a mobile phone are recovered. MobileMuster partners with TES, a global leader in electronic waste recycling, to maximise recovery rates and ensure all mobile phone components are processed in an environmentally responsible manner. Our recycling partner uses state-of-the art equipment and processing techniques to deliver the highest recovery rates with the lowest environmental impact.

When you drop off your mobile phone or post it back for recycling they are transported to our recyclers facilities in Melbourne, Sydney or Brisbane.

They are sorted and disassembled into components: batteries, printed circuit boards, casing, screens, accessories and packaging.

Materials recovered

Glass is used in the touch screen of a mobile phone. When it is recycled the glass is melted, crushed and used to produce new glass products or as a replacement material in road base and construction.

Aluminium is used in a mobile phone casing and components. It is one of the most recyclable materials. Aluminium is melted in a furnace and the liquid aluminium is then placed in moulds to create new aluminium products.

Lithium batteries are processed to recover valuable materials including steel and a mixed metal compound of graphene, nickel, cobalt and lithium that can be used to make new batteries.

Plastic can be found on mobile phone casing and accessories. Recycled plastic is processed into pellets and can be turned into new products like pallets. It requires a lot less energy than goes into making new plastic.

Environmental benefits

Everyone knows recycling is good for the environment. The environmental benefit of recycling our mobile phones is gained from avoiding future greenhouse gas emissions, saving energy, protecting the environment and conserving natural resources.

Mobile phones are made from numerous materials including precious metals and through recycling we reduce the need to mine and take less from the earth. Recycling also saves energy. When we make new products out of virgin materials, we expend energy to extract and process those materials. This includes burning fossil fuels. However, if we manufacture products using recycled materials, we reduce the need for virgin materials and save the energy required to extract and process them.

Finally, recycling reduces pollution. Recycling improves air quality by reducing the demand for power used in the mining, refining, processing and shipping of raw materials. Through recycling we are also preventing potentially hazardous materials from entering the environment.

Learn more

What's inside your mobile phone?

The environmental benefits of recycling

Circular economy

A circular economy is designed to support the repair, reuse and recycling of products so that the materials that have gone into making them retain their value and can continue to be reused. To support the circular economy it is important to extend the life of your phone where you can. Device manufacturers make it easy to update software and entire operating systems without the need to purchase a new phone. They also offer repair and reuse programs for customers and when the phone no longer works you can recycle them through MobileMuster.

MobileMuster helps to develop the circular economy in Australia, specifically we believe our role is to enhance the collection system of unwanted phones. Support repair and reuse programs to increase the lifespan of mobile phone use. Improve the material recovery process in recycling and reduce the number of phones in storage.